-

“So your mother died? So what? Serve my guests!” my husband laughed. I served the food while tears streamed down my face. My husband’s boss took my hand and asked, “Why are you crying?” I told him.

{“aigc_info”:{“aigc_label_type”:0,”source_info”:”dreamina”},”data”:{“os”:”web”,”product”:”dreamina”,”exportType”:”generation”,”pictureId”:”0″},”trace_info”:{“originItemId”:”7581677717045710088″}} Lena Moore had been moving around like a ghost all morning. At 11:50 a.m., while mindlessly chopping vegetables, she…

-

My husband thought it was funny to slap me across the mouth in front of his coworkers after I made a harmless joke. The room fell silent. He leaned toward me and hissed contemptuously, “Learn your place.” I smiled slowly, wiped the blood from my lip, and calmly replied, “You just slapped the wrong woman.” What he didn’t know was that every phone in that room had just recorded the exact moment his career died.

The comment was innocent, almost a household joke taken out of context. We were at my husband’s company’s annual dinner,…

-

I can still hear the sharp smack of his hand before the words stung even more. “See what time it is? Get in the kitchen, you useless thing!” he roared, the children freezing behind him. I swallowed the pain, smiled, and cooked in silence. When I finally put the dishes on the table, their laughter turned into shouts. What I served that night changed everything, and I was no longer afraid.

I can still hear the snap of his hand before the words stung even more. “Do you see what time…

-

My abusive husband forced me, seven months pregnant, to shower under the outdoor tap in the freezing cold. He was sure his cruelty would go unnoticed. But he didn’t know my father is a multimillionaire… and the punishment was only just beginning.

My name is Lucía Álvarez , and when it all happened, I was seven months pregnant. I lived in a cold northern…

-

The mistress attacked the pregnant wife in the hospital… but she had no idea who her father really was…

When Laura Bennett was admitted to San Gabriel Hospital, thirty-four weeks pregnant, she thought the worst was over. The doctor assured her…

-

I forced a smile as my ex-husband raised his glass and mocked me: “Look, Amelia… my new wife is better than you.” Laughter rippled around the table. My hands trembled, but not from fear. I tapped my phone screen and said calmly, “Since we’re bragging… let’s listen to what you said when you thought no one was listening.” The room fell silent. His face paled. And that recording… changed everything.

I forced a smile when my ex-husband, Javier Morales , raised his glass at that engagement dinner and quipped, “Look, Amelia … my new…

-

I lay on the operating table, my hands numb, listening to the constant beeping of the machines, when suddenly the gynecologist met my gaze and, with an almost imperceptible gesture, pressed a button, sliding a phone into the palm of my hand. She whispered, “Call the police. Now.” My heart froze. “Why?” I managed to mouth. Her voice trembled as she replied, “Your in-laws paid for this hospital… and they’re planning something after the baby is born.”

I lay on the operating table, my hands numb from the anesthesia and my mind trapped between fear and exhaustion….

-

“So what if your mother died? Stop crying and go serve the guests!” My husband forced me to serve at his promotion party on the very day of my mother’s funeral. What I didn’t expect was for a mysterious man to approach me and reveal a hidden secret about her…

“So what if your mother died? Stop crying and go attend to the guests!” Julián, my husband, pierced me like a…

-

My son hit me just because the soup wasn’t salted enough. The next morning he told me, “My wife is coming for lunch, cover it all up and smile.” Then he went to the office, and when he walked into his boss’s office, he turned as white as a sheet.

I never thought I’d end up writing this about my own son. My name is Carmen Ruiz , I’m sixty-two years old,…

-

On my 73rd birthday, my husband brought a woman and her two children and said in front of all the guests, “This is my second family. I hid them for 30 years!” Our daughters were horrified, but I smiled, handed him a box, and calmly said, “I knew it. This is for you.” He opened it… and his hands began to tremble.

My seventy-third birthday was meant to be quiet. I had organized a small gathering at home with my daughters, some…

-

I raised my glass and smiled. “I’m pregnant.” The living room glowed under the chandeliers until my mother-in-law let out an icy laugh. “Nice trick,” she said. “Are you trying to steal my son’s millions?” Before I could react, she shoved me toward the balcony railing. “Try it. Jump… or admit you’re lying.” Hours later, in the emergency room, the doctor looked at the ultrasound and said quietly, “It’s not a fake pregnancy… but what we’ve found will change this family forever.”

I raised my glass, my hand slightly trembling, and smiled, trying to keep my voice steady. “I’m pregnant.” The hotel…

-

My sister called me “fat” and coldly said, “I don’t want any fat relatives at my wedding. It’s embarrassing. Go away.” When I sought support from my parents, they just mocked me and said, “Listen to your sister.” Humiliated but silent, I decided to plan a surprise for her wedding day. And when the big day arrived, what happened left my sister and my parents completely speechless.

My name is Lucía Morales , I’m thirty-two years old, and I’ve always been “the fat sister” in the family. Not because…

-

At my son’s wedding, my daughter-in-law demanded the keys to my apartment in front of 130 guests. When I refused, she slapped me so hard the entire room fell silent. Without saying a word, I left and made a phone call. Thirty minutes later, a man appeared at the door of the reception hall… and when they saw who it was, they started to cry.

My son Daniel ‘s wedding day was supposed to be one of the happiest days of my life. The hall was packed:…

-

On our wedding anniversary, my husband announced in front of all the guests, “Twenty-five years is enough. I want someone younger. I want you out of the apartment tomorrow.” What he forgot was that the apartment was mine. So I took the microphone and said something that left him completely speechless.

On our twenty-fifth wedding anniversary, the restaurant room was filled with warm lights, wine glasses, and practiced smiles. We had…

-

A young homeless girl was reported to the police after a store manager caught her stealing a carton of milk for her two hungry siblings. A millionaire who witnessed the entire scene suddenly stepped forward…

The manager of the Martínez y Hermanos supermarket , in a central Seville neighborhood, called the police in a firm but nervous…

-

“My mom has been sleeping for three days.” A seven-year-old girl pushed a wheelbarrow for miles to save her newborn twin brothers, and what happened next left the entire hospital speechless…

“ My mom has been sleeping for three days ,” the seven-year-old girl said hoarsely as she pushed an old wheelbarrow along…

-

I stared at the hospital bill and whispered, “I don’t have that kind of money.” My boss leaned back in his chair, his expression unreadable. “One night,” he said quietly. “That’s all.” I told myself it was just a sacrifice, the only way to save my brother’s life. But when I woke up the next morning in his luxury penthouse, there was a contract beside me… and then I realized that that night I hadn’t just paid a bill: I had rewritten my future.

I stared at the hospital bill, my hands trembling. The number seemed like a mockery, printed in black ink: an…

-

During dinner, my son’s mother-in-law threw boiling soup in my face and smiled contemptuously. “That’s what you deserve!” I looked at my son, waiting for him to say something, but he just added, “She’s right, Mom.” I didn’t reply. I wiped my face, which was burning with pain, and stood up silently. I left the house without looking back, but before I left, I made a quick phone call. What happened next… they never forgot it.

The family dinner was being held in the elegant dining room of Carmen Rodríguez ‘s house , my son’s mother-in-law. Everything was…

-

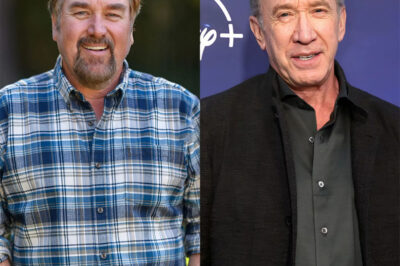

CBS has made headlines with a reported $1 billion deal to star Tim Allen and Richard Karn in a new sitcom, billed as “non-woke” comedy. This move is seen as a bold attempt to carve out a niche in the crowded TV landscape, focusing on authentic, unfiltered humor

BREAKING: CBS Drops $1 Billion on Tim Allen and Richard Karn for Bold “Non-Woke” Sitcom — Could This Be TV’s…

-

Oprah Winfrey’s supposed decision to leave America and move to Italy has sparked intense curiosity, with rumors swirling around her reasons. The alleged quote “I can’t live under the same sky as Elon Musk for the next 4 years” has fueled speculation about a feud between the media mogul and the tech billionaire. However, it’s essential to note that these claims are likely false and originated from unverified sources

SHOCKING NEWS: Oprah Winfrey Suddenly Left Everything Behind to Leave America – 8 Words Revealing the Reason That Stunned Hollywood!….